- Home

- Central Lubrication

- Progressive devices

Progressive devices

SSV PROGRESSIVE DISTRIBUTORS

SSVD PROGRESSIVE DISTRIBUTORS

SSVL PROGRESSIVE DISTRIBUTORS

SSVDL PROGRESSIVE DISTRIBUTORS

Progressive devices

Lincoln offers a comprehensive range of progressive automatic lubrication systems perfectly suited for small to medium-sized machines. These machines have distributed lubrication points with varying lubrication needs. Both the SKF ProFlex system and the Lincoln Quicklub system can be used for this purpose.

How Progressive Lubrication Systems Work

These progressive lubrication systems consist of a pump connected to at least one primary progressive metering device, also known as a master metering device. When necessary, a second-level progressive metering devices can be connected to the connections of the main metering device, increasing the number of lubrication points significantly. The outlets of both the primary and second-level dosing units are connected by branch lines to the various lubrication points of the machine.

Attention! The use of a third level of progressive metering devices is not recommended due to potential system complications.

Lubricant Distribution and Application Range

The pump supplies lubricant to the pressurized dosing units, with a capacity of up to approximately 550 bar (8,000 psi), depending on the specific pump model. The progressive metering devices ensure that the lubricant is distributed evenly over the lubrication points or according to preset amounts, depending on the specific type of progressive metering device.

This system is versatile and suitable for various applications. Lincoln offers progressive lubrication systems that can deliver precise doses of lubricant ranging from a few lubrication points to up to 150 lubrication points. Distances can vary up to about 15 meters, and in specific cases, even more than 100 meters when combined with flow restrictors in oil applications.

Various Types of Progressive Dosing Units

This article describes different types of progressive dosing units available, each with unique characteristics and applications. These include the SSV, SSVM, SSVD, and SSVDL units.

SSV

The SSV progressive metering device is a compact single block dosing device for 6 to 22 (master metering device) lubrication points. It is available with a pin indicator for visual system monitoring or with a piston detector for monitoring electrical installations. The dosing device must be ordered in separate parts, as shown in the table.

Features and benefits

Sizes up to 22 outlets

High workload

Available in different materials

Exact lubricant dosage

Unique internal crossporting technology

Optional with visual monitoring pen or with electrically monitored piston detector

Applications

Construction and Mining

Agricultural implements

Industrial equipment

Renewable energy

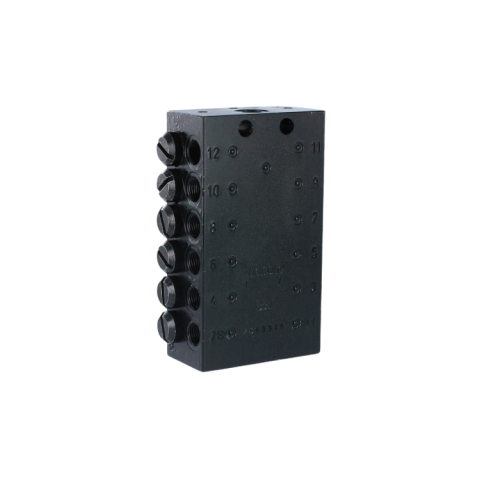

SSVD

The SSVD-type measuring device is a compact progressive single-block dosing device with adjustable output through different dosing screws. The screw provides a specific amount of output per two outputs (opposite each other), allowing for different amounts of lubricant to be applied to the lubrication points.

Features and benefits

Ten different sizes of dosing screws available

Optional visual or electrical monitoring

Nickel-plated surface treatment for a corrosive environment is available

Ideal for use as a primary metering device

Applications

Construction and Mining

Agricultural implements

Industrial equipment

SSVDL

The SSVDL metering device is a progressive metering device, suitable for larger pipe diameters, especially for applications in heavy industry. It is also available with a pin indicator for visual system monitoring. Outlet combination elements for 2, 3, 4, and 5 outlets are available.

Features and benefits

Similar to SSVD but with greater distances between outlets for larger pipe diameters

Sizes 6 to 14 outlets

High workload

Exact lubricant dosage

Optional with visual monitoring pen or with electrically monitored piston detector

Applications

Heavy industry

Continuity of Lubrication

One of the advantages of these systems is their ability to ensure continuous lubrication as long as the pump is in operation. When the pump is stopped, the plungers of the progressive dosing unit remain in their current position. Once the pumping cycle resumes, the plungers continue their movement from where they stopped. If a lubrication point becomes clogged, a blockage occurs. This blockage acts as a control mechanism, prompting maintenance personnel to inspect the system and perform maintenance.

Planning and Design of Lubrication Systems

Effective central lubrication system planning involves considering various factors. These include the number of lubrication points, back pressure at the lubrication points, operating temperature, the type of lubricant used, control and surveillance requirements, and more. Ancotech's expertise is invaluable in designing systems meeting these specifications. A well-designed central lubrication system ensures precise delivery of the right amount of lubricant at the right time, reducing wear and preventing contamination due to excessive lubrication.

Automatic Lubrication System Specialists

Ancotech Smeertechniek specializes in automatic lubrication systems and associated components. We assist both large and small companies in various sectors to enhance production output and lower energy and maintenance costs. For optimized device lubrication, contact us. Proper lubrication techniques and lubricants increase machine reliability.

Since Ancotech's inception, we've maintained a strong partnership with our quality partner "Lincoln Industrial," of which we are a dealer and importer. Additionally, we collaborate with quality brands like Lincoln, Pressol, and Graco. Over the years, we've built a diverse product range related to lubrication technology.

Order Your Progressive metering devices in Our Webshop

Know which lubricants you need? Add them to your cart directly. Current product availability is displayed. Explore other products in our webshop, add desired items, and place an order—orders placed before 3:30 pm arrive the next day! Contact us for advice or more information at (0)72-561 65 53, or complete the contact form.

Instructional Video for Clearer Understanding

For a clearer understanding of how a progressive metering device operates, Lincoln has created an instructional video. This video provides step-by-step explanations. For more insights, watch the instructional video.

{{ message }}